ABS board is a new material in the board industry. Its full name is acrylonitrile/butadiene/styrene copolymer board, which is the polymer with the largest output and the most widely used. It organically unifies the various properties of PS, SAN, and BS, and has excellent mechanical properties of toughness, hardness, and rigidity.

01. Introduction

ABS board is a new material in the board industry. Its full name is acrylonitrile/butadiene/styrene copolymer board, which is the polymer with the largest output and the most widely used. It organically unifies the various properties of PS, SAN, and BS, and has excellent mechanical properties of toughness, hardness, and rigidity.

02. Features

1. Excellent mechanical properties. Its impact strength is excellent and can be used at extremely low temperatures; ABS has excellent wear resistance, good dimensional stability, and oil resistance, and can be used for bearings under medium loads and speeds. ABS has greater creep resistance than PSF and PC, but less than PA and POM. The bending strength and compression strength of ABS are among the poorest plastics. The mechanical properties of ABS are greatly affected by temperature.

2. It is not affected by water, inorganic salts, alkalis and various acids, but it is soluble in ketones, aldehydes and chlorinated hydrocarbons. It will produce stress cracking when eroded by glacial acetic acid, vegetable oils, etc. ABS has poor weather resistance and is prone to degradation under the action of ultraviolet light; after half a year outdoors, the impact strength drops by half.

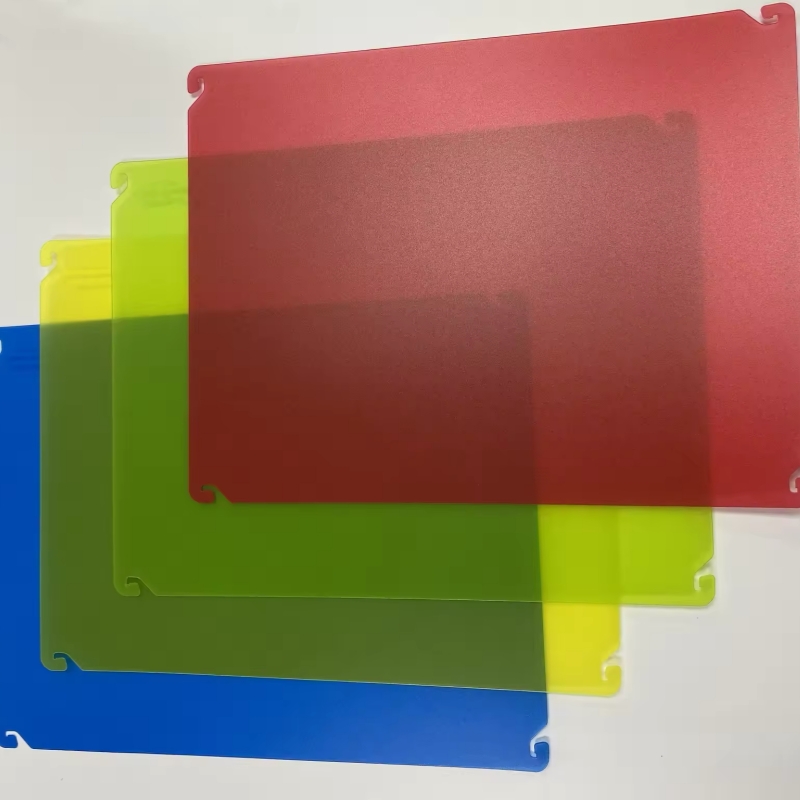

3. Excellent impact strength, good dimensional stability, dyeability, good molding and machining, high mechanical strength, high rigidity, low water absorption, good corrosion resistance, simple connection, non-toxic and tasteless, with excellent chemical properties and electrical insulation properties. It can withstand heat without deformation, and has high impact toughness under low temperature conditions. It is also a hard, scratch-resistant and deformable material. Low water absorption; high dimensional stability. Conventional ABS boards are not very white, but they are very tough. They can be cut with a shearing machine or punched with a mold.

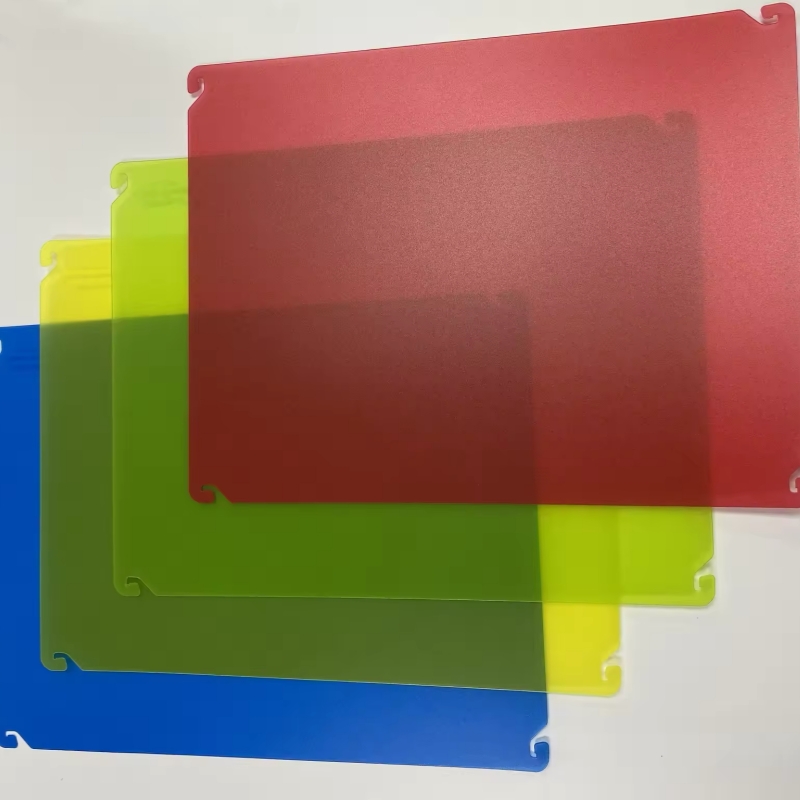

4. Low temperature resistance. The heat deformation temperature of ABS sheets is 93~118℃, and the product can be increased by about 10℃ after annealing. ABS can still show a certain toughness at -40℃ and can be used in the temperature range of -40~100℃. Among them, transparent ABS sheets have very good transparency and excellent grinding and polishing effects, and are the preferred material to replace PC sheets. Compared with acrylic, it has very good toughness and can meet the delicate processing of products.

03. Application

1. Home appliance field. ABS board can be used as the shell and internal components of electrical appliances such as TV, radio, washing machine, refrigerator, telephone, air conditioner, etc.

2. Auto parts. ABS plastic board is used to make auto parts such as shell, adjustment handle, door lining, control switch knob, duct, etc. ABS is mainly used for impact resistance, such as strength, rigidity and formability. Accessories include fenders, armrests, ventilation cover plates, supports, buffer expansion plates, etc.

3. Office equipment. Using the excellent impact resistance, excellent rigidity, dimensional stability and formability of ABS board, it is economical and practical to manufacture the shells of various office equipment. Office equipment such as fax machines, copiers, typewriters and computer monitors have higher requirements for fire protection, so generally flame retardant ABS is used in the order of preference.

4. Mechanical ABS plastic shell can be used to produce mechanical equipment and general mechanical parts. Such as water tank, appearance shell, electric cabinet, battery tank, gear bearing, pump impeller mold model and fasteners, bolts, cover plate.

5. Mold model. Due to the superior processing performance, light weight and low price of ABS plastic, it has been widely used in the manufacture of home appliance industry, automobile, mechanical equipment, and testing instrument mold models in recent years. At present, the world's leading three-dimensional prototype made of ABS as the standard material, then you can make any appearance shape, suitability and related function model of the new product you want to test in a flying size machine. It has the best performance-price ratio among similar products.

04. Production process

ABS board production process can be divided into upstream and downstream processes.

Upstream process refers to smelting, casting, hot rolling, cold rolling, etc., which are the same as other high-precision plates and strips.

Downstream process refers to heat treatment, surface treatment, stretching and bending correction, lubricant application, longitudinal and transverse shearing, precision cutting and deep processing, etc. Its downstream process is much more complicated than other high-precision plates and strips, and there are many more processes. It can be briefly expressed as: unwinding-heat treatment, air cushion furnace (can be heated by fuel, electricity or electromagnetic induction) solution treatment (temperature 500~600℃) or annealing, water quenching/air quenching-surface treatment (cleaning and conversion treatment)-stretching and bending-lubricating-coiling, etc.

05. The difference between ABS board and PVC board

1. Raw materials: ABS board is acrylonitrile/butadiene/styrene copolymer board; PVC board is a vacuum blister film.

2. Application: ABS board is widely used in food industry parts, building models, hand-made board production, phased electronic industry parts, refrigerator refrigeration industry, electronic and electrical fields, pharmaceutical industry, auto parts, etc.; PVC board is widely used in chemical industry, petroleum, electroplating, water purification equipment, environmental protection equipment, mining, medicine, electronics, communications and decoration, etc.

ABS board is acrylonitrile/butadiene/styrene copolymer board; PVC board is a vacuum blister film.