(Acrylonitrile-styrene-butadiene copolymer, ABS is the abbreviation of Acrylonitrile Butadiene Styrene) is a thermoplastic polymer material structure with high strength, good toughness and easy processing. It is also called ABS resin. ABS material is a graft copolymer of three monomers: acrylonitrile (Acrylonitrile), 1,3-butadiene (Butadiene), and styrene (Styrene)

(Acrylonitrile-styrene-butadiene copolymer, ABS is the abbreviation of Acrylonitrile Butadiene Styrene) is a thermoplastic polymer material structure with high strength, good toughness and easy processing. It is also called ABS resin. ABS material is a graft copolymer of three monomers: acrylonitrile (Acrylonitrile), 1,3-butadiene (Butadiene), and styrene (Styrene). Its molecular formula can be written as (C8H8·C4H6·C3H3N)x, but in fact it is often a mixture of graft copolymer containing butadiene and acrylonitrile-styrene copolymer, among which acrylonitrile accounts for 15%~35%, butadiene accounts for 5%~30%, and styrene accounts for 40%~60%. The most common ratio of emulsion ABS is A:B:S=22:17:61, while the proportion of B in bulk ABS is often lower, about 13%. The molding temperature of ABS plastic is 180-250℃, but it is best not to exceed 240℃, at which time the resin will decompose.

With the adjustment of the proportion of the three components, the physical properties of the resin will change to a certain extent:

1,3-Butadiene provides low-temperature ductility and impact resistance for ABS resin, but too much butadiene will reduce the hardness, gloss and fluidity of the resin;

Acrylonitrile provides hardness, heat resistance, acid, alkali and salt resistance and other chemical corrosion properties for ABS resin;

Styrene provides hardness, processing fluidity and product surface finish for ABS resin.

ABS molding and characteristics

1. Amorphous material, there are many varieties and brands, and the electromechanical properties and molding characteristics of each variety are also different. The molding method and molding conditions should be determined according to the variety

2. Strong hygroscopicity, the water content should be less than 0.3%, must be fully dried, and plastic parts requiring surface gloss should require long-term preheating and drying

3. Medium fluidity, overflow material is about 0.04mm (fluidity is worse than polystyrene and AS, but better than polycarbonate and polyvinyl chloride)

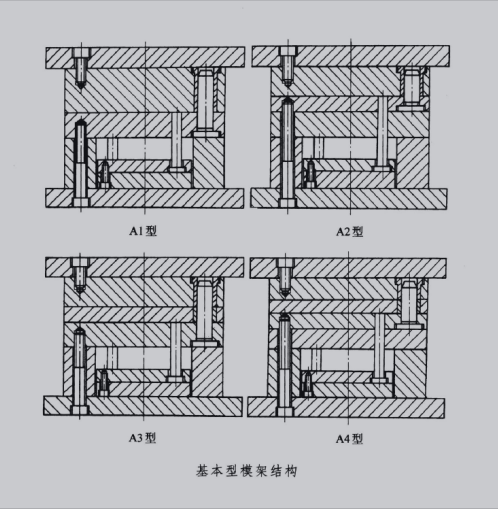

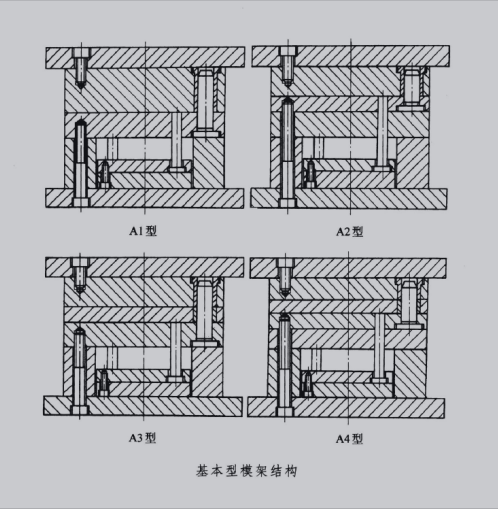

4. It is more difficult to process than polystyrene, and it is advisable to take high material temperature and mold temperature (for heat-resistant, high impact and medium impact resins, the material temperature should be higher). The material temperature has a greater impact on the physical properties, and the material temperature is too high and easy to decompose (the decomposition temperature is about 250℃, which is easier to decompose than polystyrene). For plastic parts requiring higher precision, the mold temperature should be 50-60℃, and for glossy and heat-resistant materials, it is advisable to take 60~80℃, injection pressure should be higher than that of polystyrene. Generally, the material temperature is 180~230℃ and the injection pressure is 100~140Mpa when using a plunger injection machine, and 160~220℃ and 70~100MPa for a screw injection machine. 5. When designing the mold, attention should be paid to the small resistance of the pouring system to the material flow, the appearance of the gate is poor, and welding marks are prone to occur. Attention should be paid to the selection of the gate position and form. The ejection force is too large or the surface of the plastic part shows "white" marks during mechanical processing (but it can disappear when heated in hot water). The demoulding slope should be more than 2°. Basic mold frame structure

Advantages of ABS materials:

1. Good comprehensive performance, high impact strength, chemical stability, good electrical properties

2. Good welding with 372 organic glass, made into two-color plastic parts, and can be chrome-plated and painted

3. High impact resistance, high heat resistance, flame retardant, enhanced, transparent and other levels.

4. The fluidity is slightly worse than HIPS, better than PMMA, PC, etc., and has good flexibility.

Disadvantages of ABS materials:

Low heat deformation temperature, flammable, poor weather resistance.

Overview: ABS 707k is used as the material

1) Plastic parts must be preheated and dried for a long time at 80-90 degrees for 3 hours to achieve a bright surface gloss.

2) The mold temperature should be 60-80 degrees to achieve good heat resistance.